Waterproofing NFL Raiders Field

Building an award-winning home for the NFL Raiders.

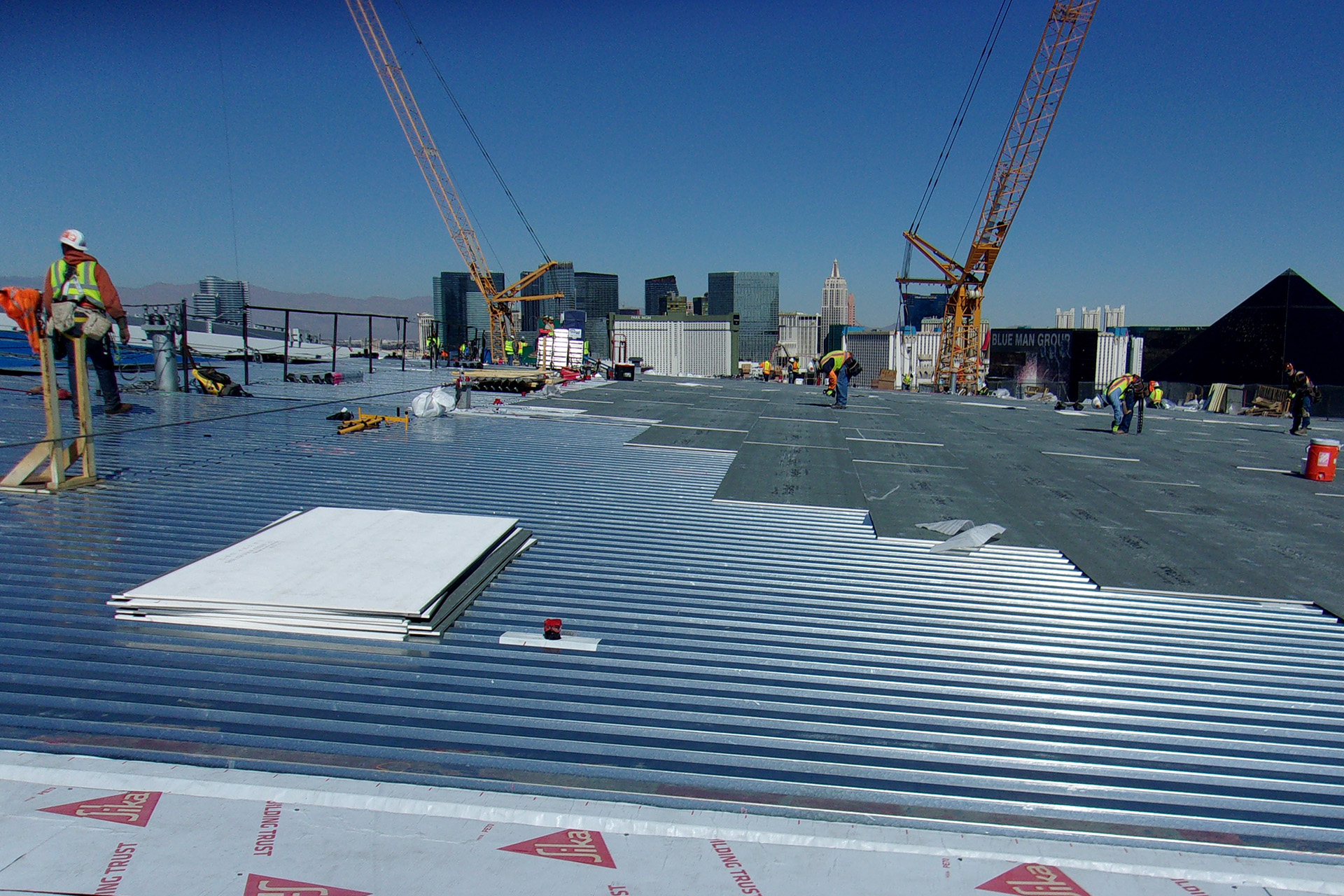

Las Vegas Allegiant Stadium, Photo Credit: Eberhard Southwest

PROJECT NAME

Allegiant Stadium

DESCRIPTION

This project began as a concept for converting a dirt lot into a modern hi-tech mega stadium. The contractor Mortensen has been involved with many such stadiums across the Country however, they teamed up with General Contractor, McCarthy Contractors to build a team of talented local subcontractors. Eberhard Southwest Roofing was awarded the multi-million-dollar contract for all waterproofing and roofing.

The first part of the waterproofing initiative was so far underground that it will never be seen again. It had to be a first-class installation the first time around. Most of the early challenges came from working deep in a massive hole dug for all the footings and foundation work to be done. Wind, dust, cranes (the size of skyscrapers), trucks and people were so many that safety had to be everyone’s priority. The below grade walls are some 30’ down from grade level. Waterproofing of these walls were done as the building sections were completed using Bituthene sheet membrane from GCP. The horizontal waterproofing was achieved with American Hydrotech 6125 Hot Rubber monolithic membrane. Not only were plaza decks and pedestrian walkways done but waterproofing was installed over the entirety of the playing field itself, about 85,000 square feet. The field is built on a tray that rolls on steel tracks. This “field tray” moves from inside the stadium to the outside for sunshine, rain, and manicure. When the tray is positioned outside of the stadium the concrete floor can be used for concerts and other events.

Up to the roof, 170’ above the Las Vegas skyline Eberhard Southwest Roofers installed 325,000 square feet of new roofing. It took loading 96 semi-trucks of roof material, for a total of 1,384 crane pics. Coordination of the crane loading was challenging, as staging areas were tight and there were multiple other cranes in use throughout the job. Once loaded, a base layer of Densdeck prime was installed over the metal structure followed by a peel and stick vapor barrier membrane to act as a temporary waterproofing so work could continue inside. The roofing consisted of two layers of polyiso insulation followed by another layer of Densdeck prime all mechanically fastened to the structure followed by 80 mil Sarnafil PVC membrane fully adhered on top. Sarnafil membrane was used to prepare the stadium logo and installed on the rooftop. The logo was prepared on the ground (smallest letter was 40’ tall), transported onto the roof, laid out using GPS coordinates for design accuracy, and welded into place.

For anyone entering or working on the roof deck, the contractor required 100% full-time body harness fall protection 100% of the time, with good reason. We vigilantly paid close attention to positioning of our crews, equipment, and ropes to confirm that progress was not hindered but safety was not compromised. The crews fought wind, rain, varying extreme temperatures, and a daily climb up many flights of stairs as the service elevator became inaccessible to rooftops. On this project our work was some of the first to be done and some of the last. With 50 plus skilled roofing mechanics, well thought out work plan, highly trained personnel for their specific roll, and a Safety Director who was on site full-time throughout the entire period, we finished on schedule and accident free.